Lot-sizing Algorithms in Flexible Manufacturing Systems with Simulation Experiments

Abstract

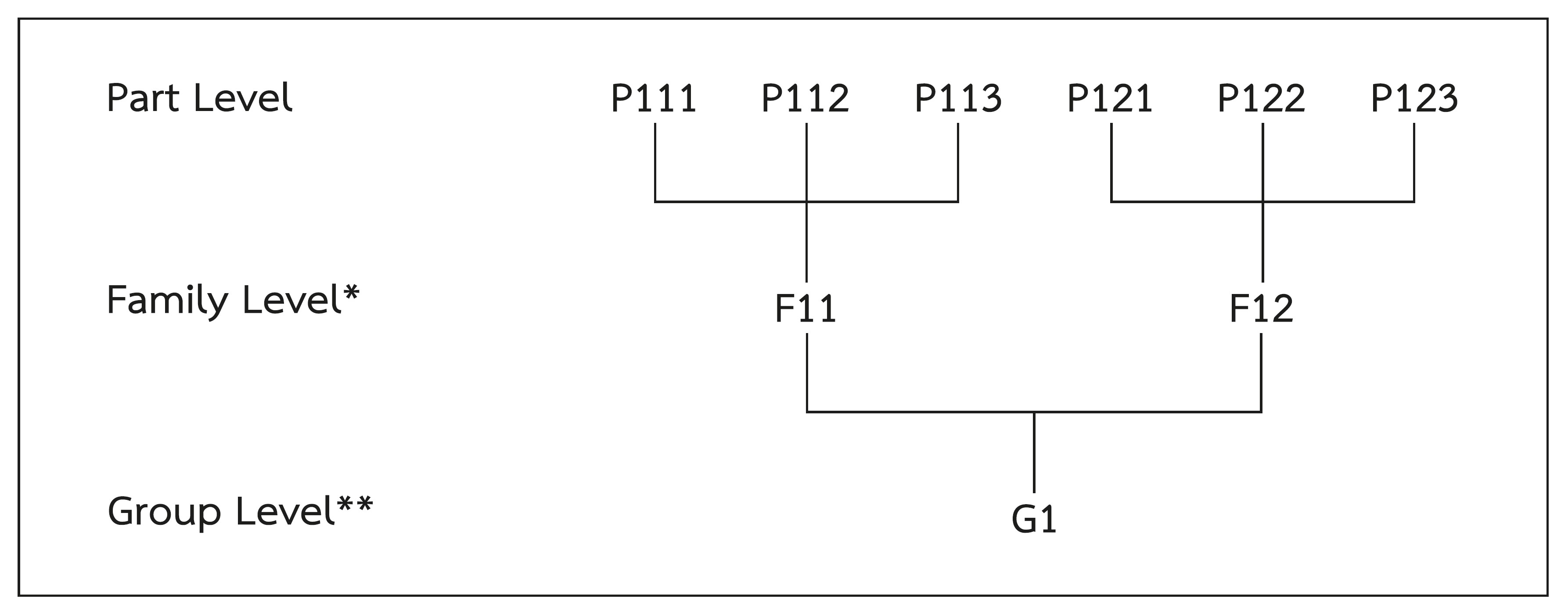

A flexible manufacturing system (FMS) is a manufacturing system for producing goods that is readily adaptable to changes in the product being manufactured, both in type and quantity. Machines and computerized systems are configured to manufacture different parts and handle varying levels of production. This research focuses on lot-sizing decisions which are critical to the successful implementation and operations of FMS. The objectives of the research are to explore how some of the traditional lot-sizing algorithms currently available in the job shop production systems may be modified to accommodate the unique characteristics and operating environments of FMS, and to conduct a series of simulation experiments to evaluate the performance of the proposed lot-sizing algorithms in hypothetical FMS under a selected set of operating conditions.

References

Arn, E. (1975). Group technology. Heidelberg: Springer-Verlag. https://doi.org/10.1007/978-3-642-66262-1

Burbidge, J. L. (1975). The introduction of group technology. New York: Wiley.

Burbidge, J. L. (1979). Group technology in the engineering industry. London: Mechanical Engineering Publications Ltd.

Devries, M., Harvey, S., & Tipnis, V. (1976). Group technology: An overview and bibliography. Cincinnati, Ohio: The Machinability Data center.

Edwards, G. A. B. (1971). Readings in group technology cellular systems. London: The Machinery Publishing Co., Ltd.

Fogarty, D. W., & Barringer, R. L. (1984). Scheduling manufacturing cells and flexible manufacturing systems. Proceedings of the Zero Inventory Philosophy and Practices Seminar, 104-110.

Fogarty, D. W., & Barringer, R. L. (1987). Joint order release decisions under dependent demand. Production and Inventory Management, 28(1), 55-61.

Gallagher, C. C., & Night, W. A. (1973). Group technology. London: Butterworths.

Ham, I., Hitomi, K., & Yoshida, T. (1985). Group technology: Applications to production management. Boston: Kluwer-Nijhoff Publishing. https://doi.org/10.1007/978-94-009-4976-8

Hyer, N. L. (Ed.). (1984a). Group technology at work. Dearborn, Michigan: Society of Manufacturing Engineers.

Hyer, N. L. (1984b). The potential of group technology for U.S. manufacturing. Journal of Operations Management, 4(3), 183-202. https://doi.org/10.1016/0272-6963(84)90011-1

Hyer, N. L., & Wemmerlov, U. (1982). MRP/GT: A framework for production planning and control for cellular manufacturing. Decision Sciences, 13(1), 681-701. https://doi.org/10.1111/j.1540-5915.1982.tb01899.x

Hyer, N. L., & Wemmerlov, U. (1984). Group technology and productivity. Harvard Business Review, 62, 140-149.

Levulis, T. S. (1978). Group technology - A review of the state of the art in the United States Chicago, Illinois: K.W. Tunnell Company.

Mitrofanov, S. P. (1966). Scientific principles of group technology. (English translation), J. Grayson (Ed.), London: National Lending Library for Science and Technology.

Patterson, W. J., & LaForge, L. R. (1985). The incremental part period algorithm: An alternative to EOQ. Journal of Purchasing and Materials Management, 21 (2), 28-33. https://doi.org/10.1111/j.1745-493X.1985.tb00132.x

Petrov, V. A. (1966). Flow line group planning. (English translation), E. Morris (Ed.), Yorkshire: National Lending Co. Petrov, V. A. (1968). Flow line group production planning. London: Business Publications.

Rabbi, M. F., & Lakhamani, G. (1984). Relationship between group technology and material requirements planning. Proceedings of the 1984 Annual International Industrial Engineering Conference, 483-486.

Ranson, G. (1972). Group technology. London: McGraw-Hill. Suresh, N. C. (1979). Optimizing intermittent production systems through group technology and an MRP system. Production and Inventory Management, 20 (4), 77-84.

Wemmerlov, U., & Hyer, N. L. (1987). Research issues in cellular manufacturing. International Journal of Production Research, 25 (3), 413-431. https://doi.org/10.1080/00207548708919850

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 https://creativecommons.org/licenses/by-nc-nd/4.0/

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.